In the oil and gas industry, there are four methods of transport: rail, sea, over-the-road and pipeline. Pipelines are the ideal mode of transport, providing a distinct advantage over all other modes. They bear lower risks, are far more efficient and operate at a fraction of the costs of all other modes.

The two largest issues facing midstream operators today are aging infrastructure and limited pipeline capacity. The continued development of tight oil and shale gas has pushed the constraint of existing infrastructure. In order to capture associated gas in tight oil plays, capitalize on available resources and offset the amount of gas being vented or flared into the atmosphere, new infrastructure developments are necessary.

The EIA reported that 20,000 miles of new natural gas transmission pipelines were put in service between 1998 and 2008, representing an additional capacity of 97 billion cubic feet per day. Approximately 30,000 miles of new pipelines are currently scheduled for development to bring U.S. tight oil and shale gas to market. To realize the benefit of additional pipeline capacity and decrease the potential for any unexpected outages, there is an increased demand for defect-free X70 and X80 grades API 5L line pipe.

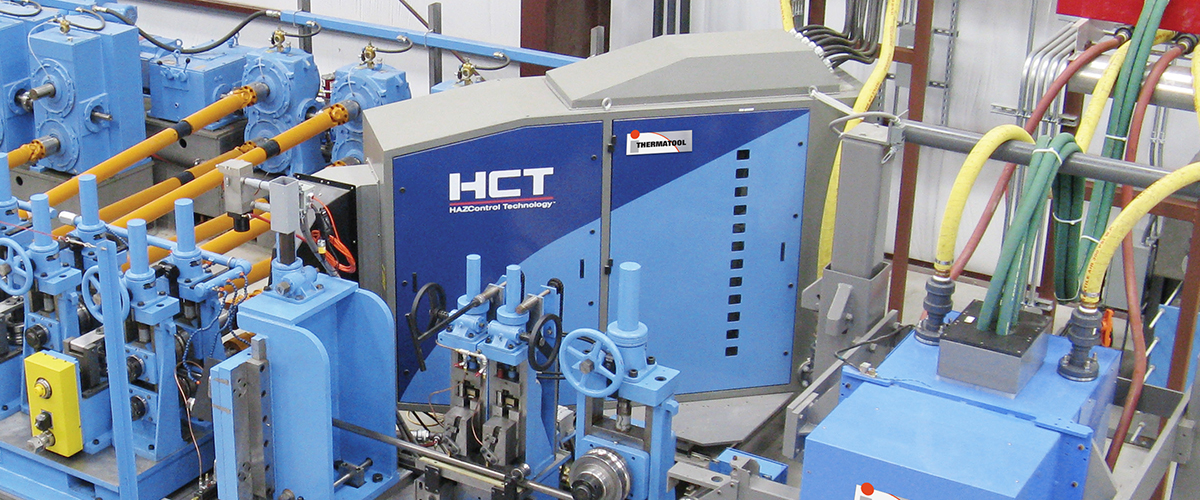

How Thermatool supports the oil country tubular goods industry

Thermatool’s technologies enable operators to produce API-grade, high-quality oil country tubular goods (OCTG). They have overcome challenges of welding advanced infrastructure materials by developing a collection of high-frequency welders, seam annealers, quench and tempering units and associated power supplies. They are able to precisely control weld heat input during HF Welding operations, minimizing any amount of changes to the parent material, which results in the highest-performing, high-frequency, welded API tube and pipe.

To read the full article and to learn more about how Thermatool products support the oil country and tubular goods (OCTG) industry, please visit GlobalSpec.com.